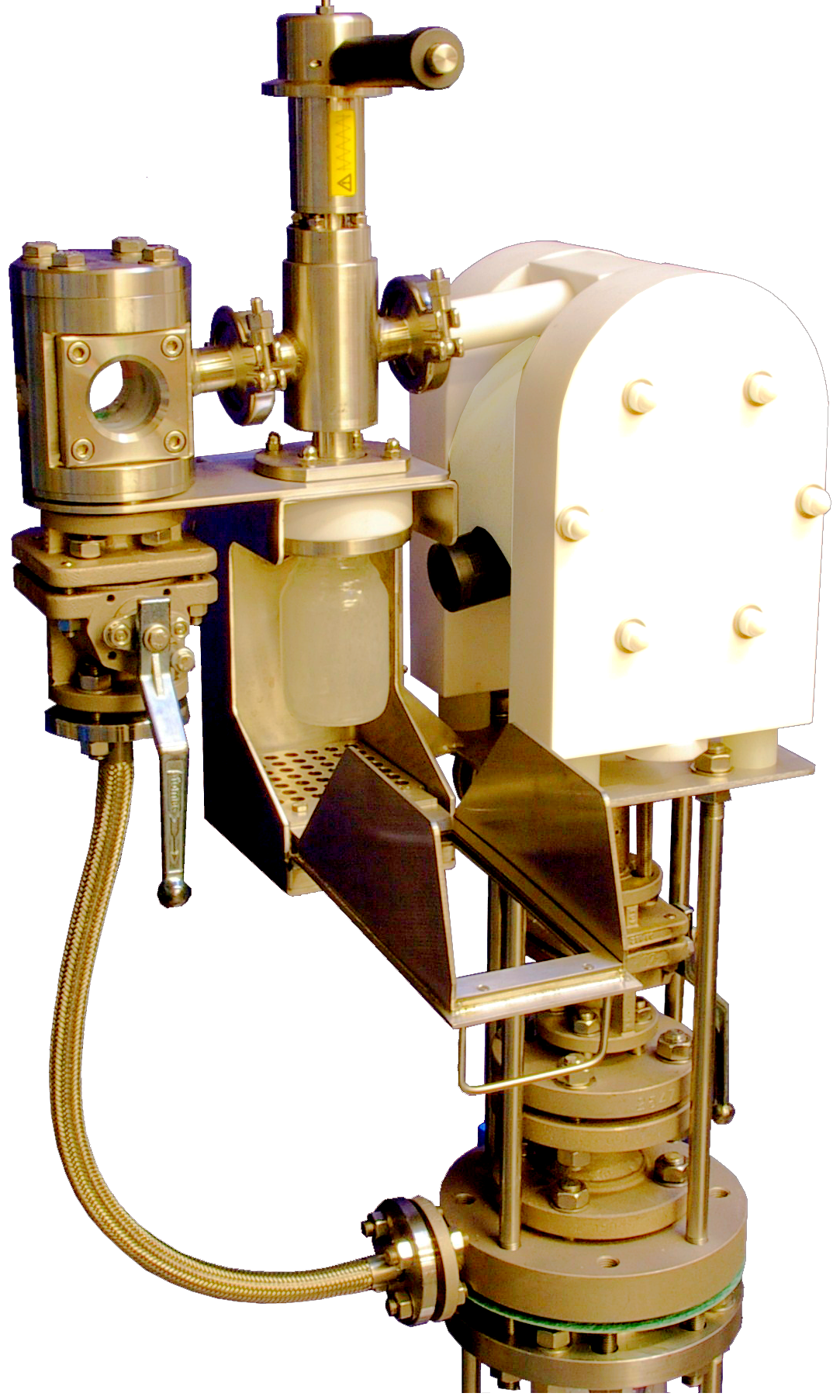

Recirculating Vessel Samplers

Our recirculating sampling systems use a pneumatically operated pump to first create suction to draw the sample, which could be highly corrosive liquor, up a dip tube mounted on the vessel lid into the system then to pump it around the system, before discharging it back into the vessel.

The sampler can be run for several seconds beforehand to ensure that there is a representative sample passing through the system before a sample is taken.

Once a sample has been obtained, the inlet isolation valve is closed and gas such as nitrogen is introduced into the system to purge the system clear ready for the next use. A wash liquor can also be used and pumped around the system and discharged into the vessel if required.

Choice of mounting position

Discharge from the pump back into the vessel can be to a separate nozzle or to the same nozzle and is connected via an instrument tee that sits underneath the dip pipe.

This allows the return liquor to fall back into the vessel around the outside of the dip pipe whilst fresh sample liquor is drawn up the bore of the dip pipe from the submerged end. The discharge to the vessel can be through a PTFE hose assembly or hard piped using our HiPerFlon lined piping.

Choose from a variety of pumps

There is a wide choice of pumps available and we typically try to follow the customers site standard. Double diaphragm pumps machined from solid PTFE blocks are suitable for use up to 212° F, beyond that we supply our sampling systems with a tubular diaphragm pump which can be used in processes up to 356°F.

Sample highly corrosive chemicals

The materials of construction are usually PFA / PTFE lined with borosilicate glass viewing windows and PTFE seals. These are chosen to allow the samplers to be used to sample highly corrosive processes containing HCL, Sulphuric acid etc.

Customers specify recirculating sampling systems where they require in-process sampling of batches of product as they are mixed in reactor vessels, to ensure the correct parameters are achieved, allowing them to adjust the chemistry as required whilst producing the batch of product.

The sample is dispensed from the system as the pump drives the sample of the vessels contents through the system. CRP use a SD-IL-400 inline sampler with lockable spring return handle as this provides simple operation and robust construction. We include a sight glass which could be a tubular or bulls eye type for visual indication of flow around the system.

Sensors can be added to our sampling systems

Many additional features and functions can be integrated into our recirculating sampling systems, such as, pH probe mounts, powder seeding option, turbidity sensors, temperature sensors etc. Additional features such as double isolating actuated valves can also be included.

CRP are here to discuss the requirements with our customers and arrive at the best solution.

Applying our years of experience in vessel contents sampling, we have created our Compact Recirculating Sampling System which incorporates all the best features in a small spaced envelope.

Usually we would use Atomac ball valves in our design, knowing that they offer excellent sealing performance and have provided decades of service to our customers. The PFA lined valves are perfect to control the flows through our sampling systems and so are our first choice.

Safety cabinets are recommended

We would recommend that the sample bottle is contained within a safety cabinet to protect the bottle, operator and environment. Our standard cabinet is stainless steel with a laminated glass door.

Please download a copy of our questionnaire to help specify a sampling system.