PFA Lined Control Valves

Control valves are used to accurately and precisely throttle the flow of gas or liquid in a pipeline, as part of a larger control system to maintain a desired characteristic. This could be a set temperature, an ideal product mix ratio, or a necessary pressure level. Control valves are operated by a pneumatic actuator, which in turn is controlled by a feedback loop such as a simple pressure or temperature transponder.

At CRP, we offer the Kammer control valve, featuring a robust, thick-walled body lined with PFA to effectively resist corrosion. The valve linings are meticulously applied in the same facility as the Atomac ball valves in Ahaus, Germany, where a rich legacy has been established through the utilization of cutting-edge, high-quality fluoropolymer molding processes.

These valves can also be supplied in a static dissipating PFA lining, for those applications where there may be a concern of static build up within the valves.

While each control valve process application may have a minimum and maximum flow requirement, Kammer control valves provide a wide selection of ‘trims’ to provide the required flow control. The right flow characteristics can be achieved with a careful selection of the right port and spindle design. Several different trims are available for each valve size.

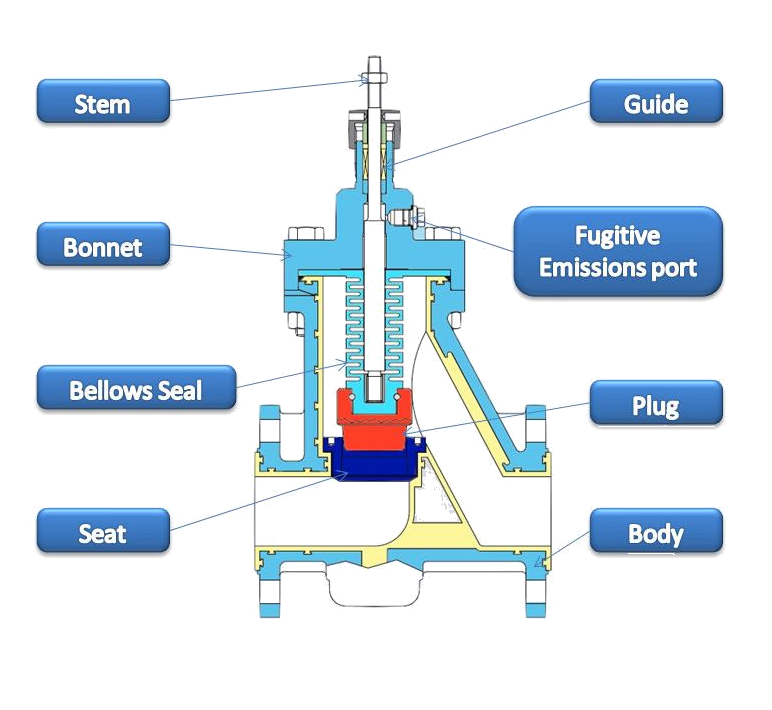

The operation of the Kammer control valve follows a linear pattern and is grounded in the globe valve principle. In this mechanism, the stem is raised or lowered into the seat, regulating the flow by adjusting the aperture to either increase or decrease it.

Specially crafted and adapted PTFE bellows are employed to seal the stem, meeting TA-Luft certification standards – ISO 15848 part 1 / Class B-C. The integrity of all bellows seals are rigorously tested at around 250°F under 87 PSI conditions.

The range of valve sizes starts at ½”NB up to 6”NB and is available with ASME 150 or DIN PN10/16 flanges. Machined ‘T’ slots within the body anchor the lining to the casting, making it suitable for use from full vacuum to 232 PSI whilst the temperature range is -20 to + 392°F. (Please consult the temperature / pressure chart for more info).

Although each valve is specially manufactured to order, Kammer keeps extensive stocks of component parts at their facility in Essen, Germany, enabling us to still offer quick delivery times.