The unique properties of PTFE processing have made it indispensable in various industries requiring corrosion-resistant and high-performance solutions. Its ability to withstand extreme temperatures and resist chemical reactions makes it a preferred material for demanding applications. Engineers and procurement specialists are constantly exploring efficient methods to produce PTFE components that meet the specific needs of chemical processing, pharmaceuticals, and food and beverage industries.

Extrusion Method for Continuous PTFE Profiles and Tubing

The extrusion process is a standard technique for manufacturing continuous PTFE profiles and tubing. This method involves pushing PTFE material through a specially designed die, which shapes it into the required form. Extrusion is particularly advantageous for creating lengthy, uniform PTFE pieces with consistent cross-sections. It’s a highly efficient process, favored for its ability to produce PTFE components in large volumes while maintaining precise dimensions. The resulting products find use across various industries that require continuous lengths of PTFE.

Compression Molding for Creating PTFE Sheets and Rods

Compression molding is a popular method for fabricating PTFE sheets and rods. In this technique, PTFE powder is placed into a mold, which is then subjected to heat and pressure. The combination of these forces causes the PTFE powder to fuse, resulting in a solid piece molded to the desired shape and size. This method is especially effective for producing large, flat sheets or cylindrical rods of PTFE, which can later be machined into more intricate shapes. Compression molding is valued for its ability to create dense, high-quality PTFE components with minimal material waste.

Skiving Method for Producing Thin PTFE Films and Tapes

The skiving method is employed to produce thin PTFE films and tapes. This process involves continuously shaving or slicing thin layers from a large block of PTFE using a sharp blade. The resulting films and tapes are incredibly thin and flexible, making them ideal for applications where space is constrained or where the PTFE needs to conform to irregular surfaces. Skiving is a precise and efficient method, enabling the production of PTFE films and tapes with uniform thicknesses, widely used in sealing and insulating applications.

Ram Extrusion for High-Volume Production of PTFE Products

Ram extrusion is a technique designed for the high-volume production of PTFE products. In this method, PTFE powder is loaded into a chamber, where a ram pushes it through a heated die. The heat causes the PTFE to fuse, forming a continuous shape as it exits the die. Ram extrusion is particularly efficient for producing large quantities of PTFE components, such as rods and tubes, in a relatively short period. This method is widely used in industries that demand bulk production of PTFE parts with consistent quality and precise dimensions.

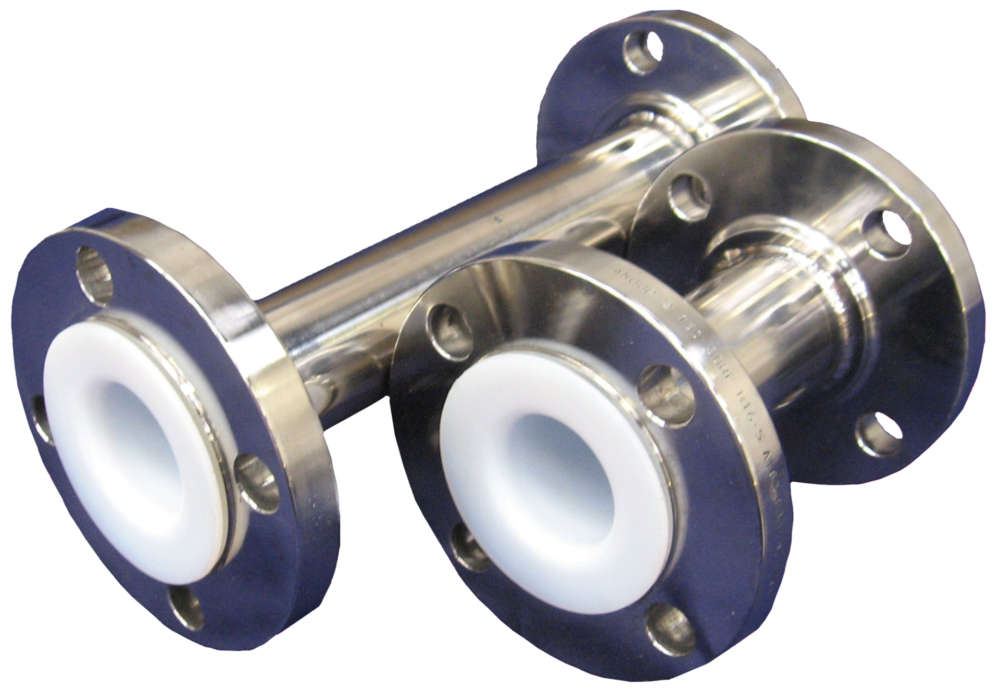

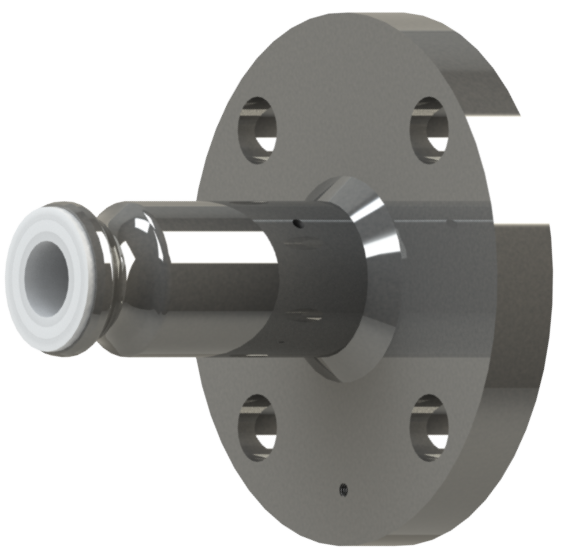

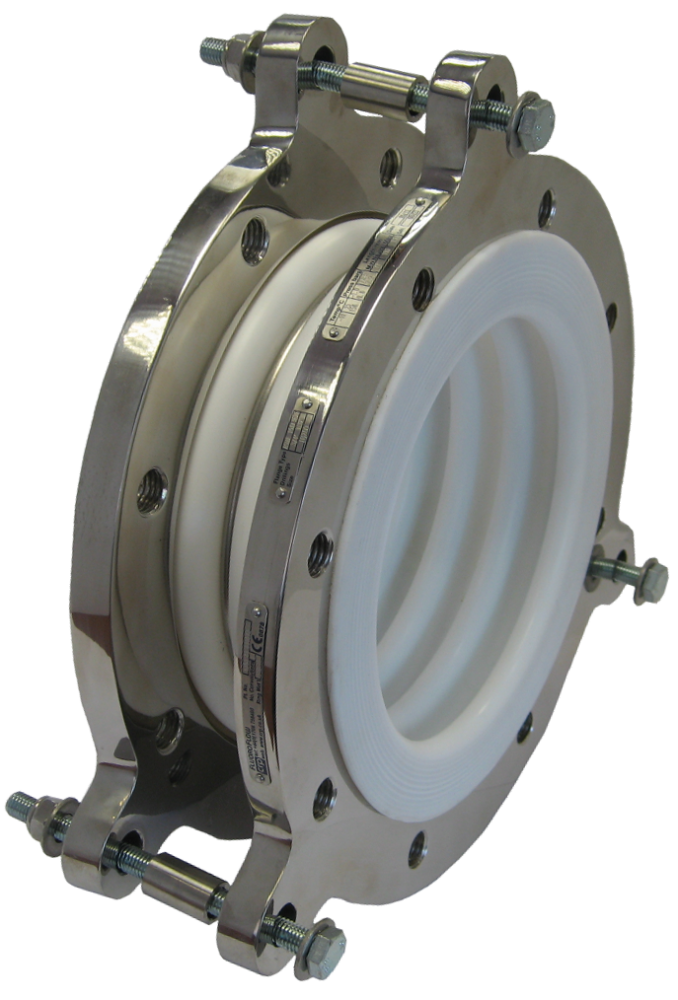

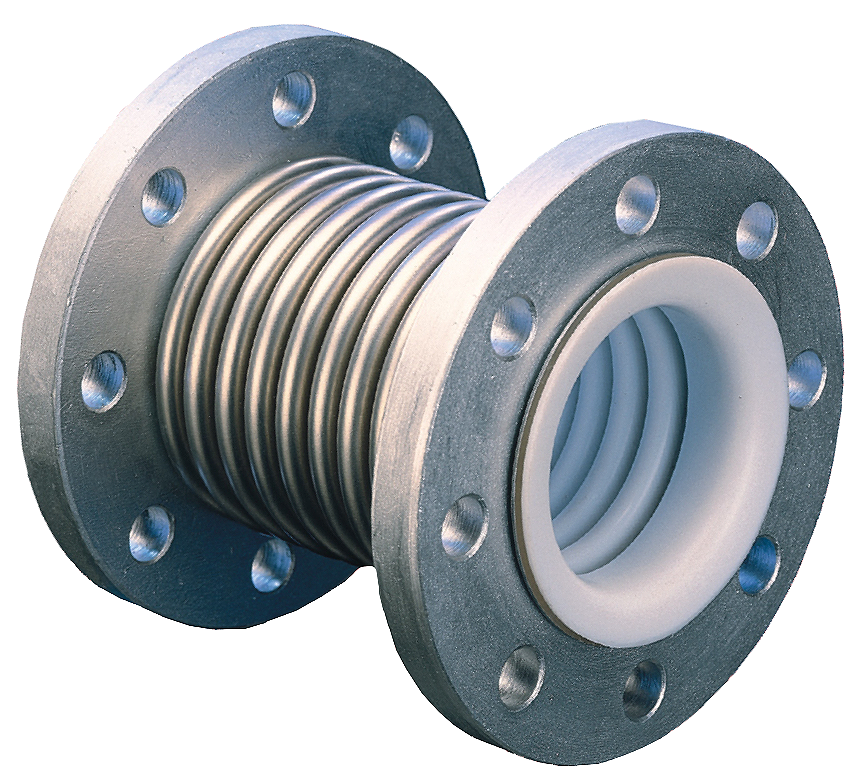

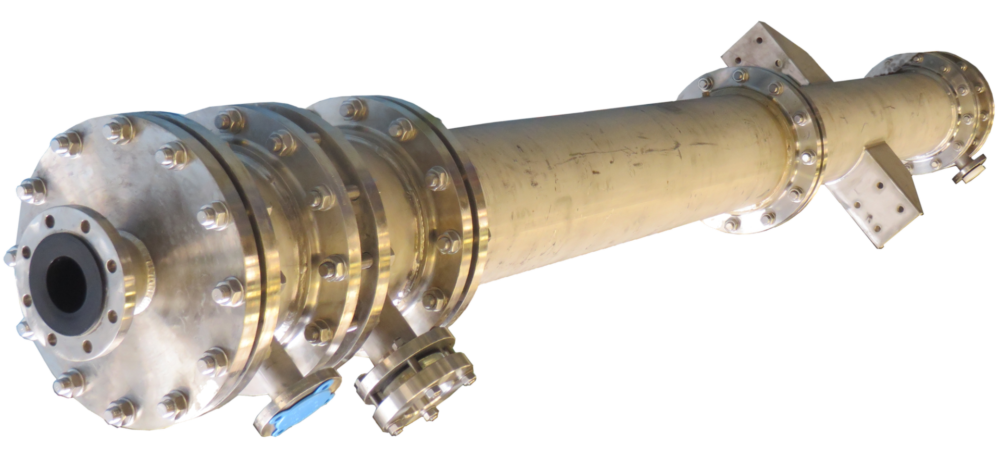

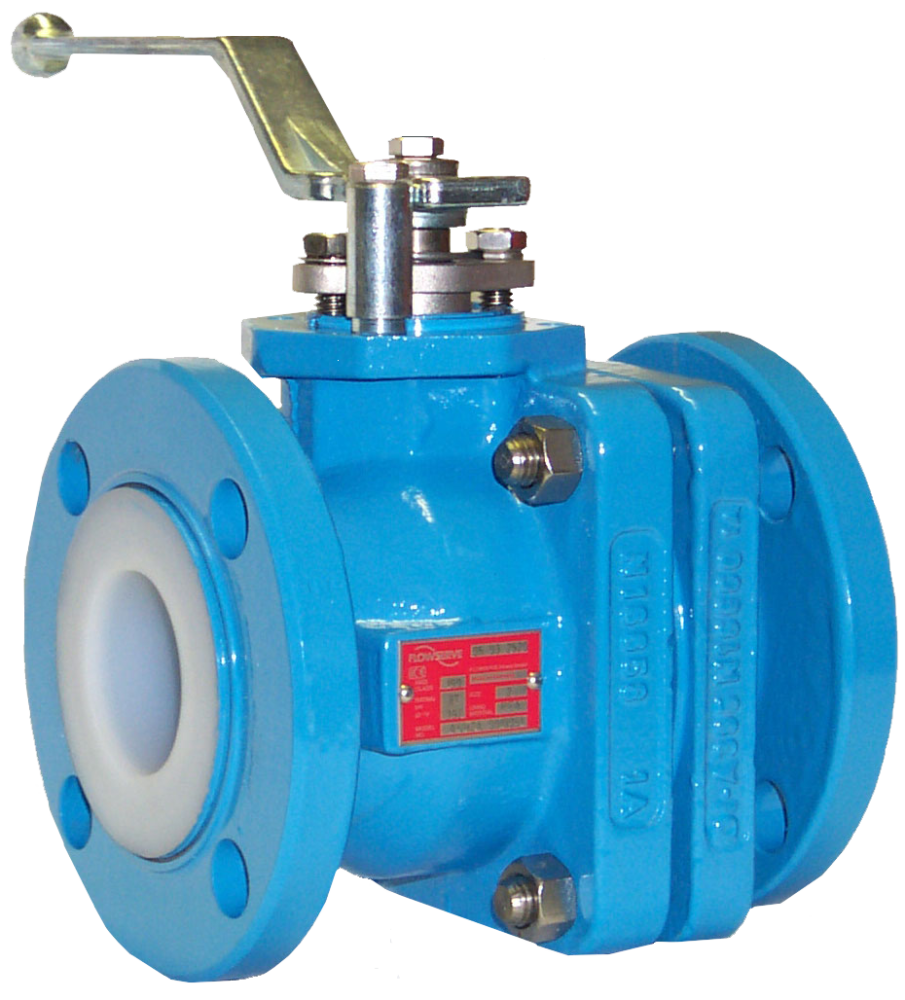

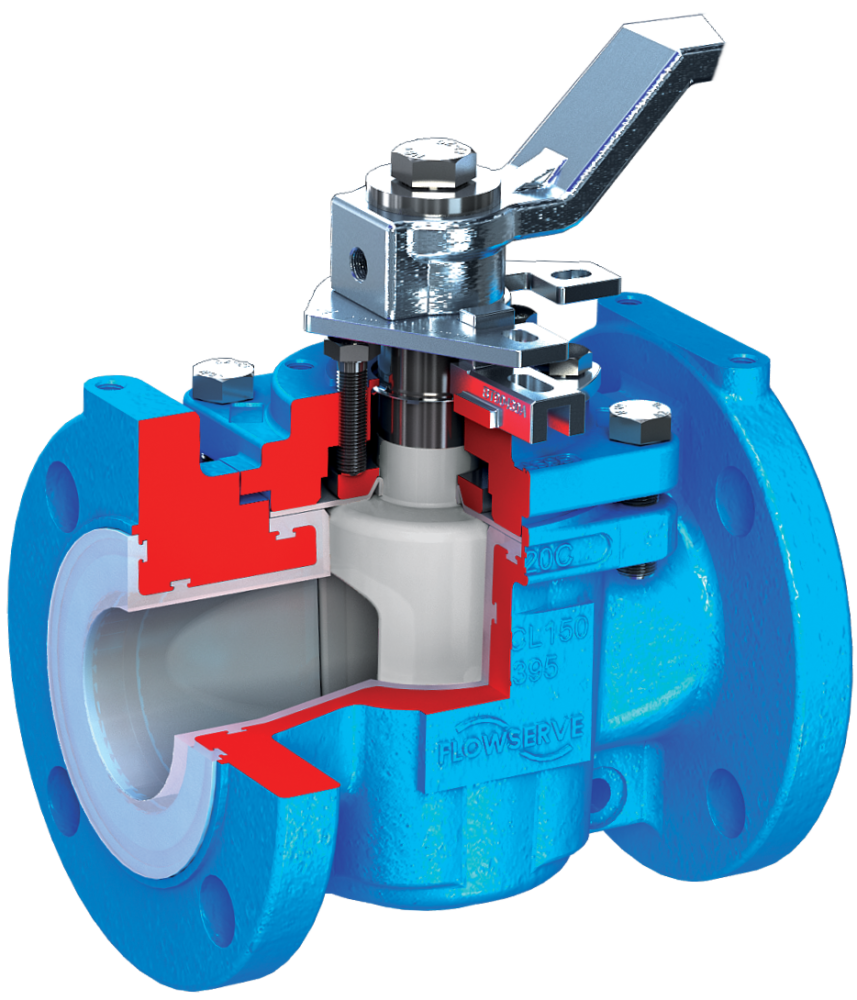

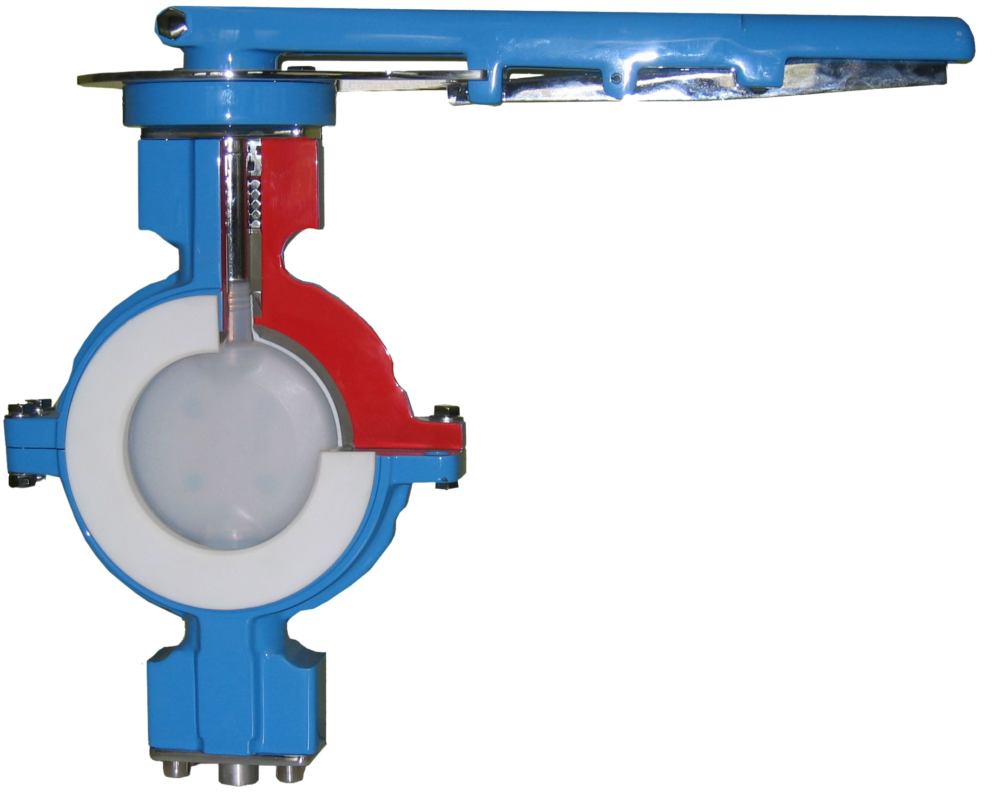

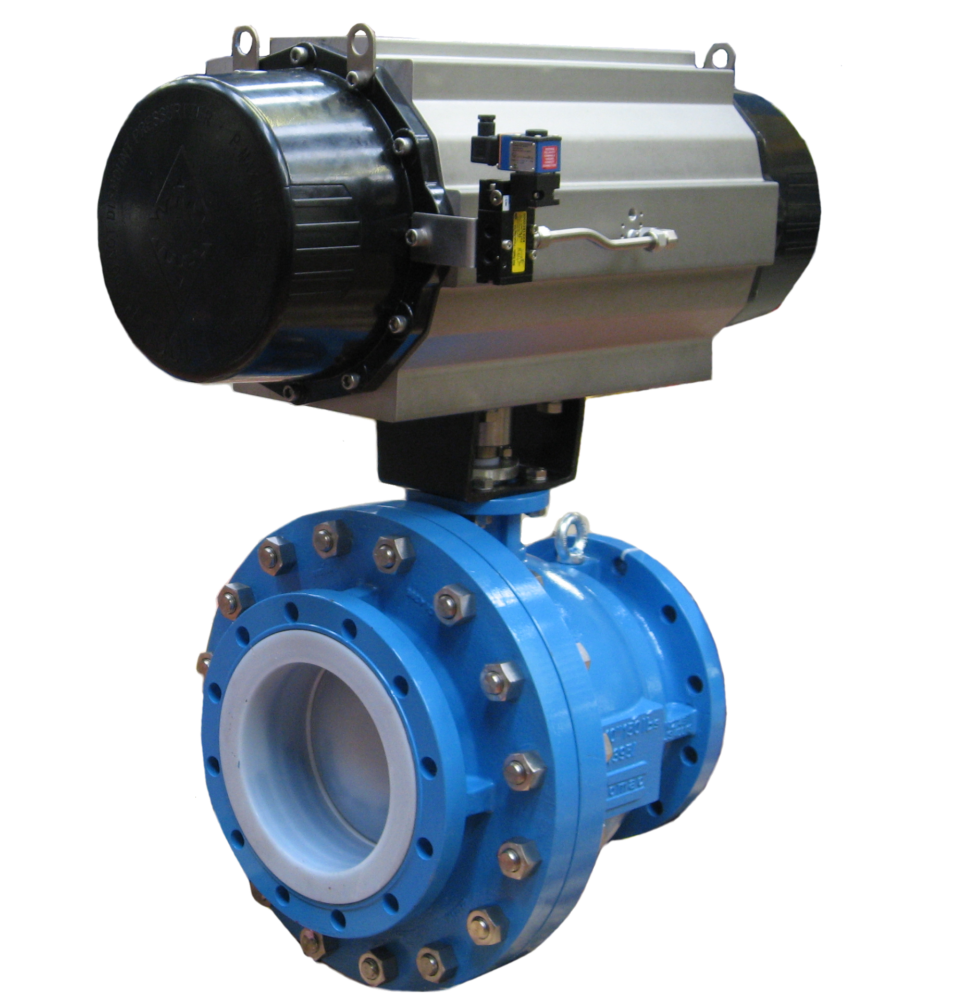

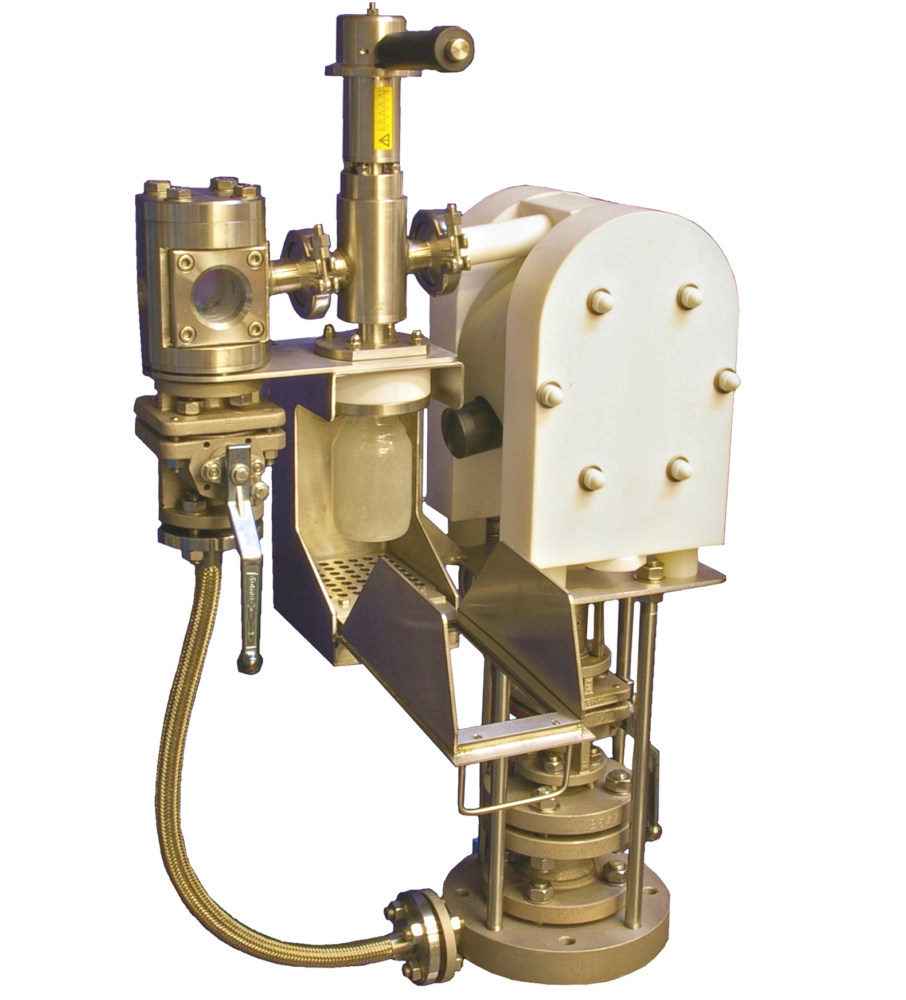

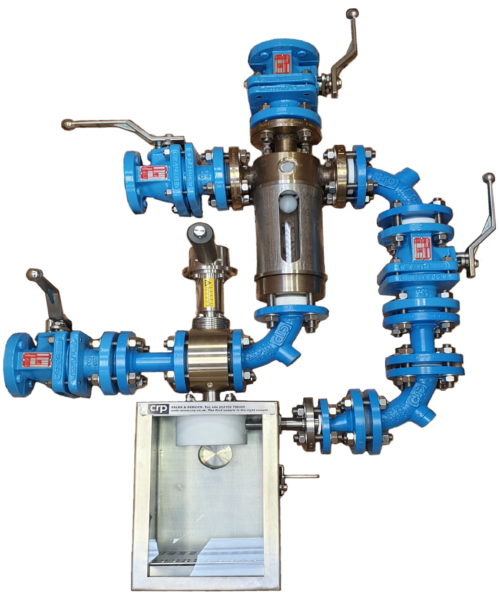

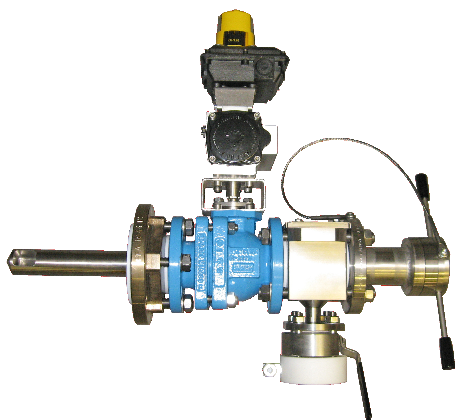

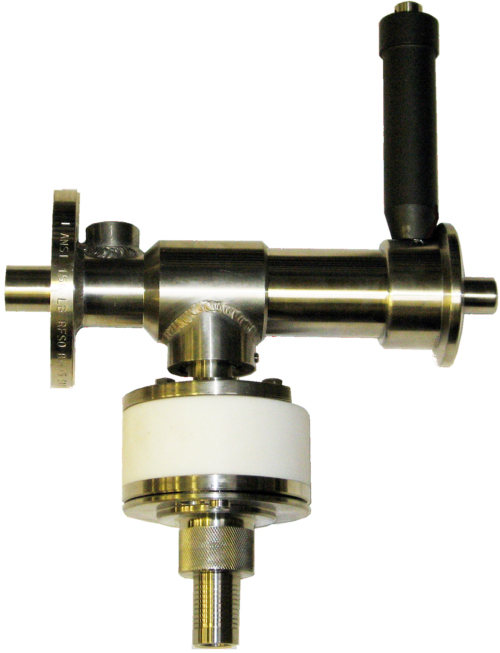

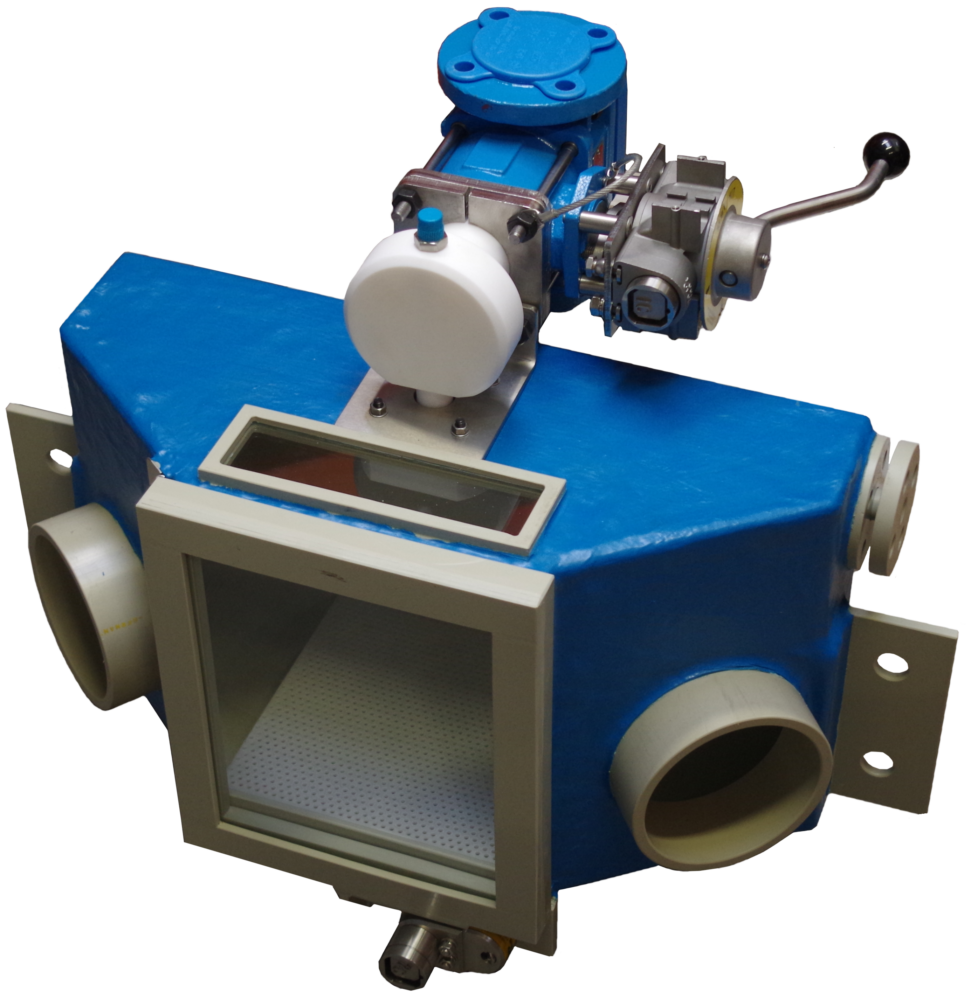

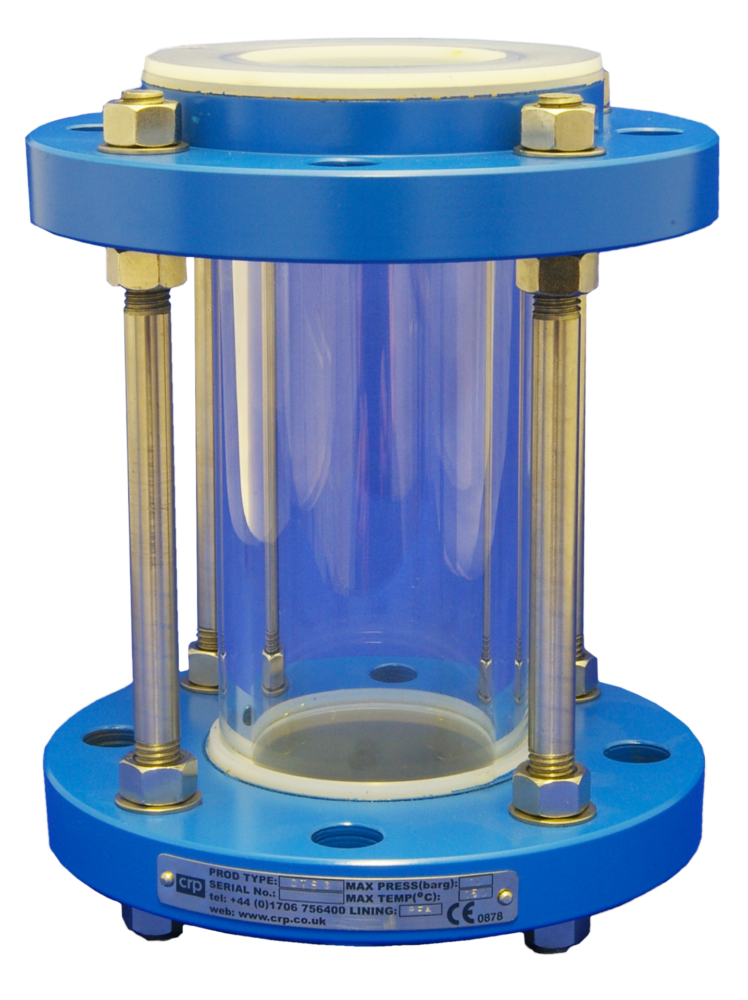

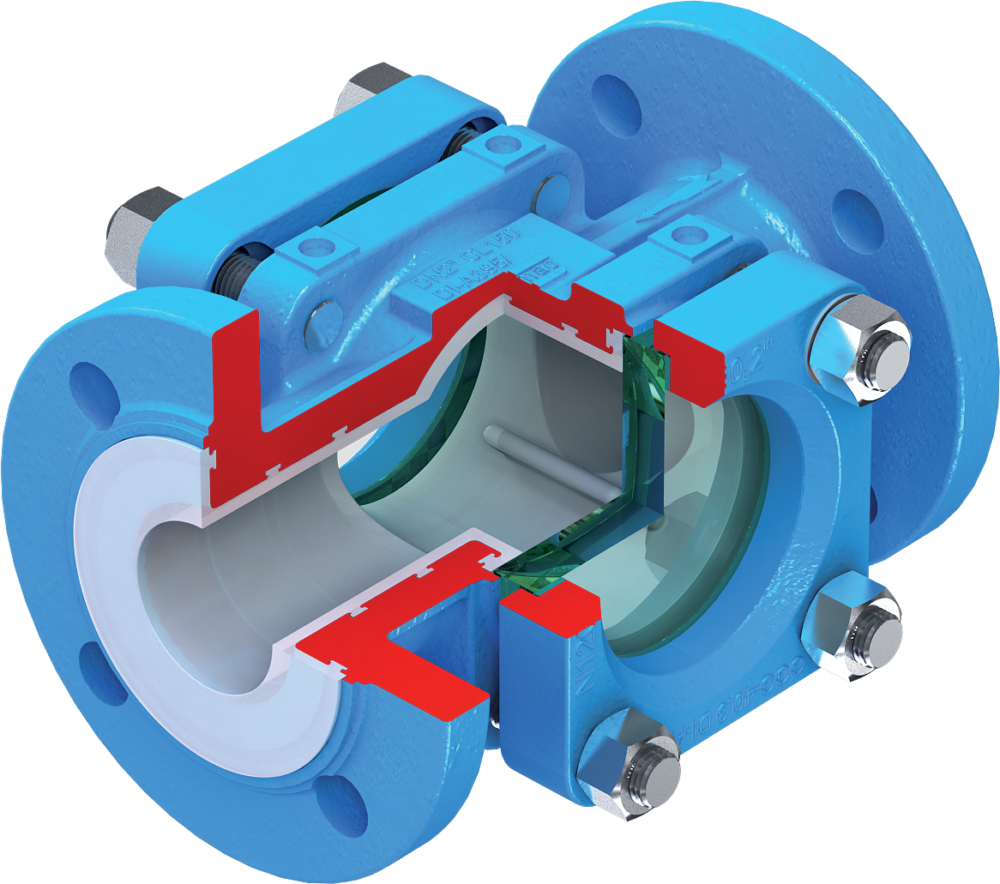

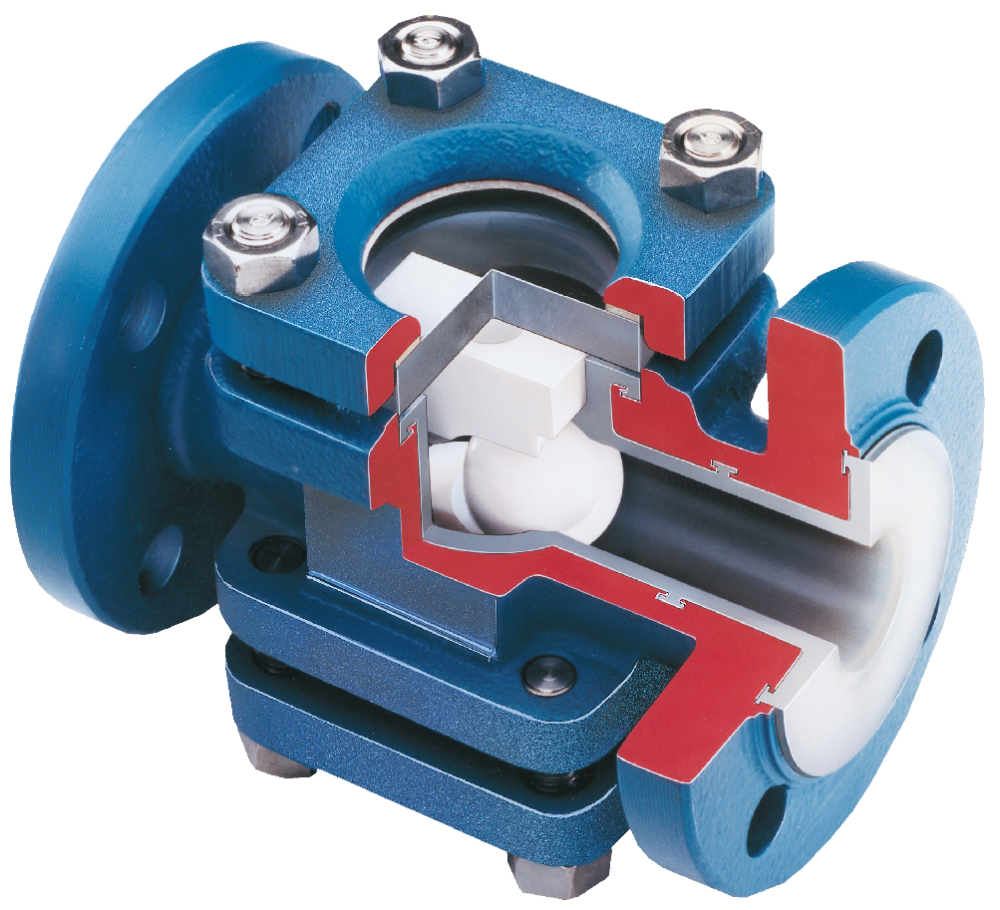

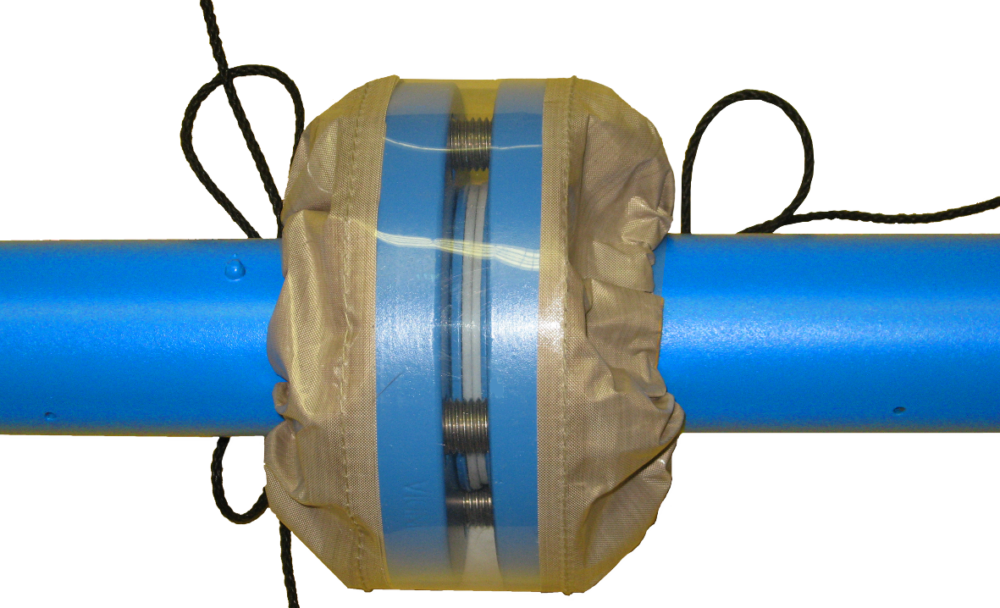

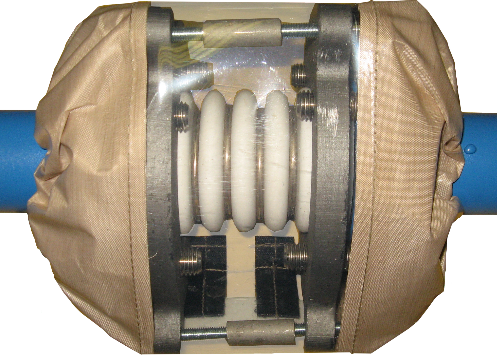

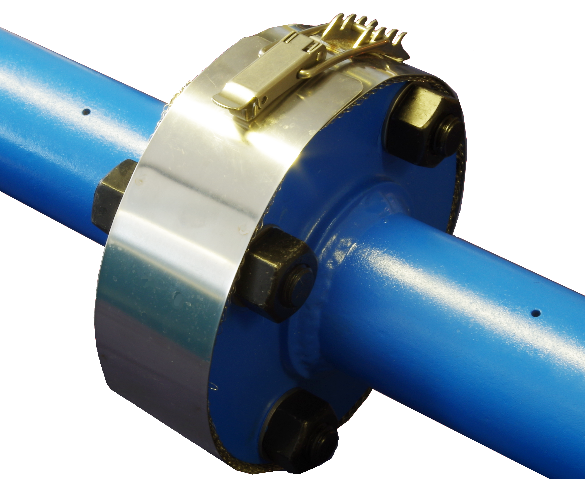

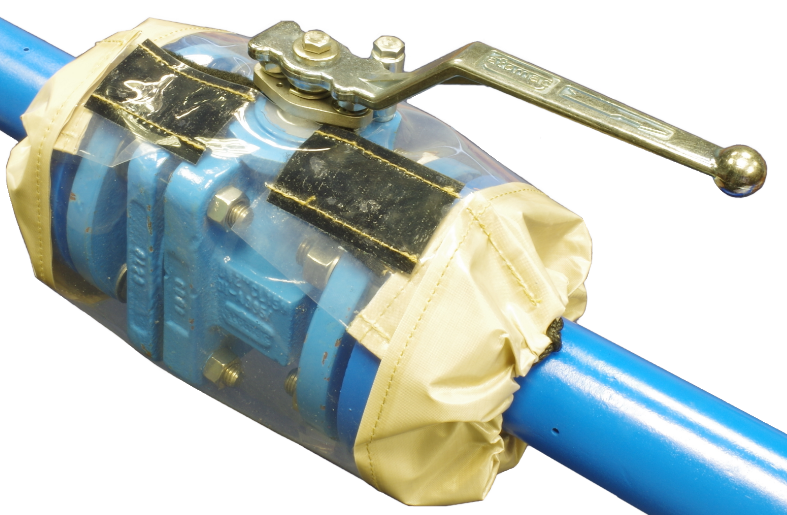

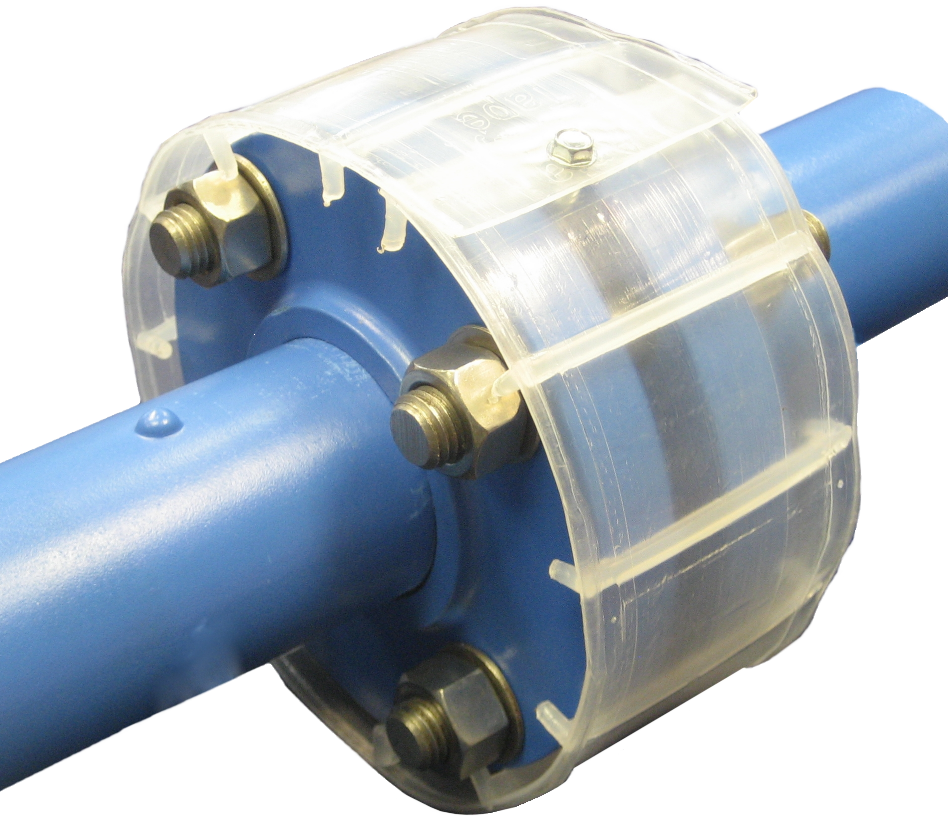

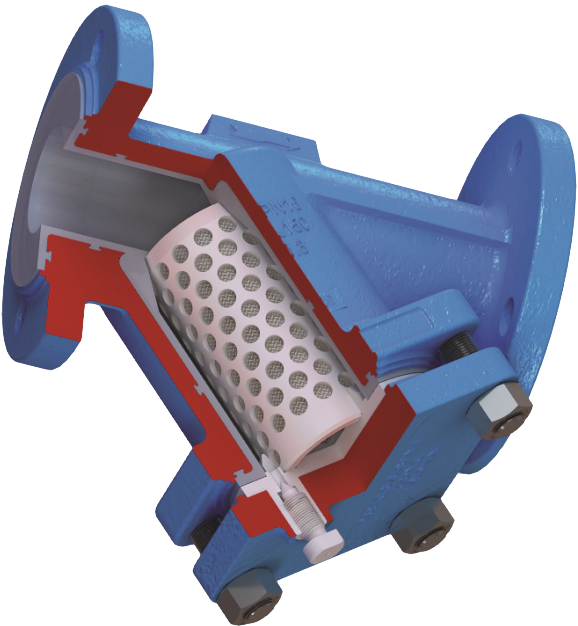

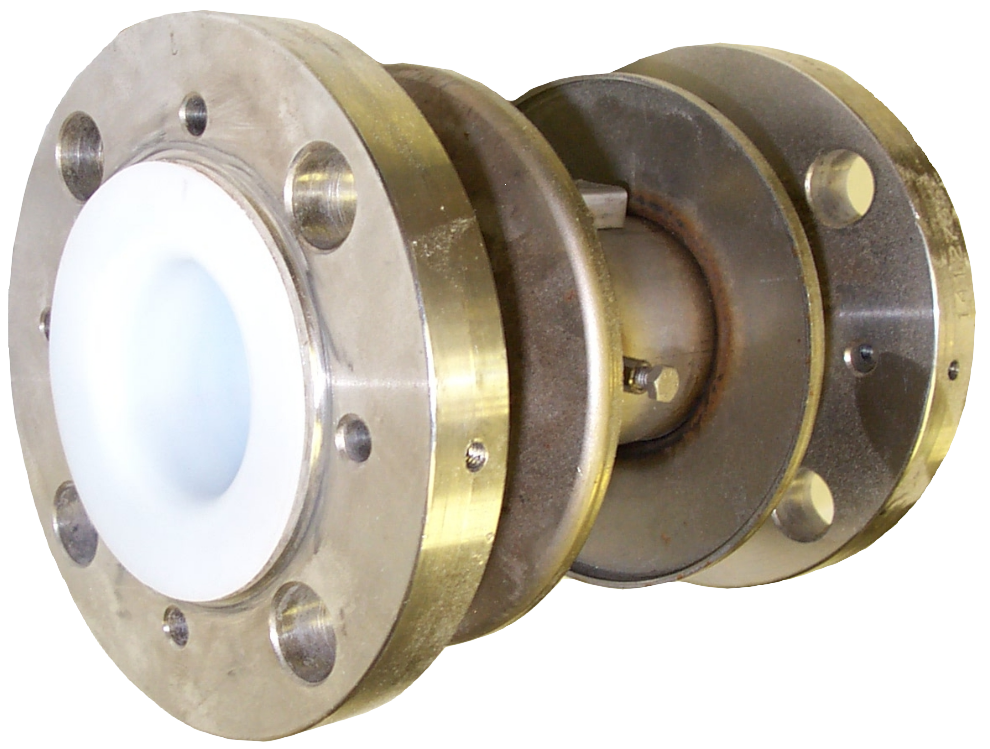

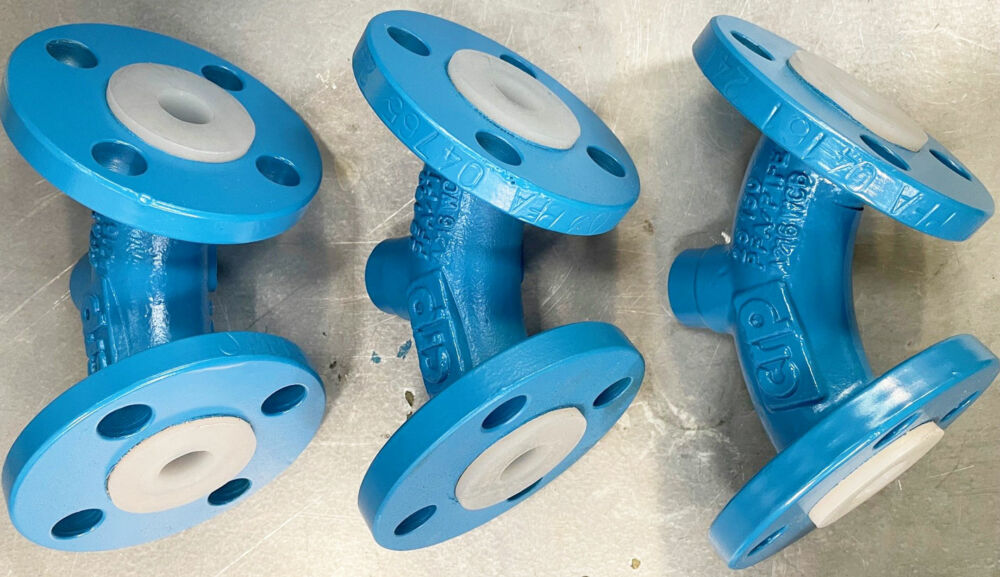

Custom PTFE-Lined and PFA-Lined Products for Industrial Needs

When it comes to confirming the longevity and reliability of your industrial systems, PTFE-lined steel services offer unmatched protection against corrosion, maintaining that your piping and equipment stand up to the harshest environments. At Corrosion Resistant Products, we provide top-tier PTFE-lined steel services designed to meet the exacting standards of your operations. Additionally, our PFA-lined products deliver exceptional chemical resistance and durability, making them ideal for transporting highly corrosive materials.

At Corrosion Resistant Products, we prioritize your satisfaction by delivering solutions that excel in performance and reliability. Contact us today and let us help you protect your systems with our industry-leading PTFE and PFA-lined steel solutions, guaranteeing unmatched durability and reliability in the most challenging environments.